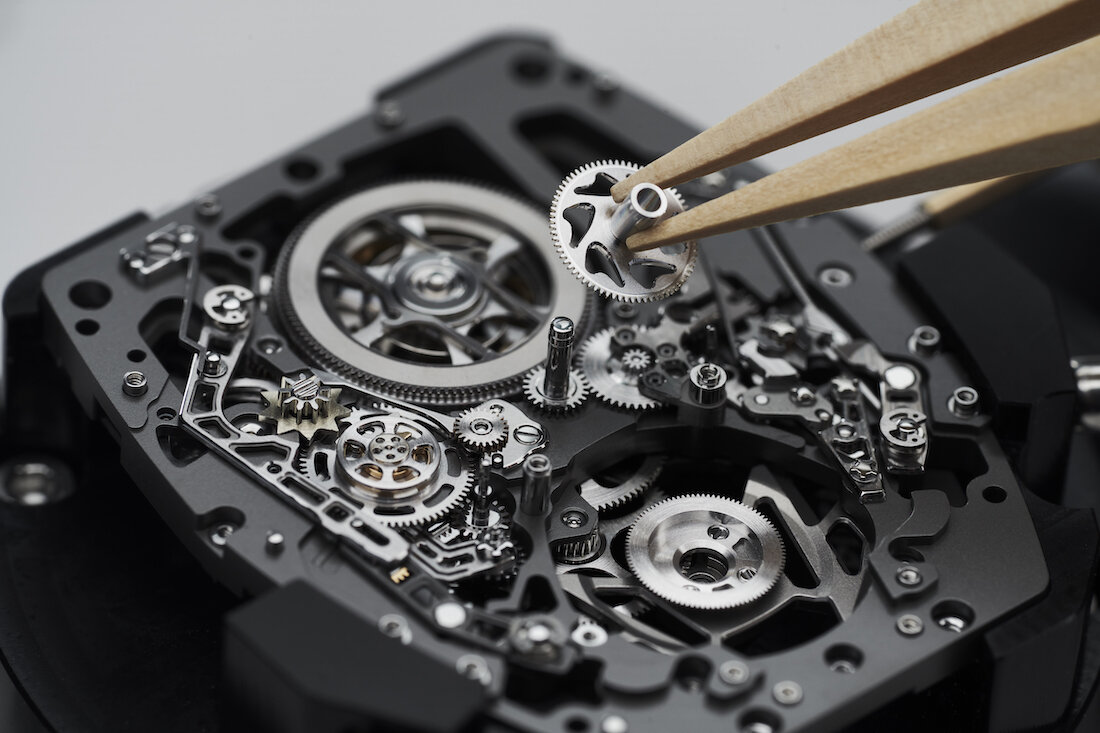

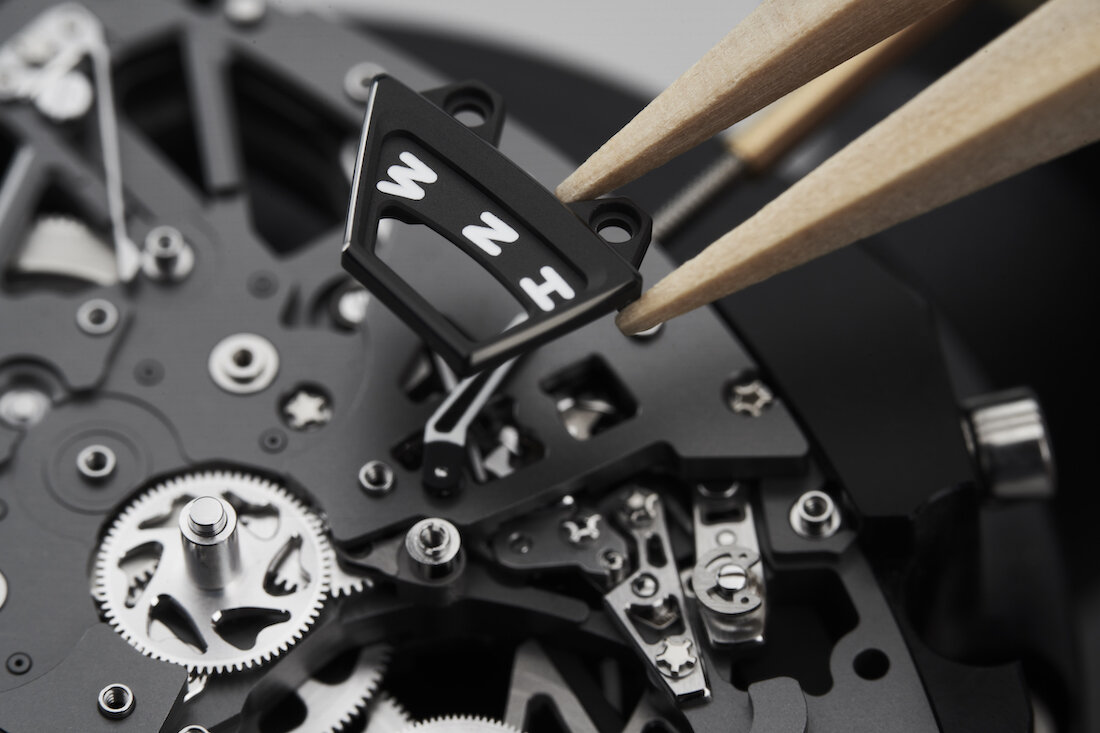

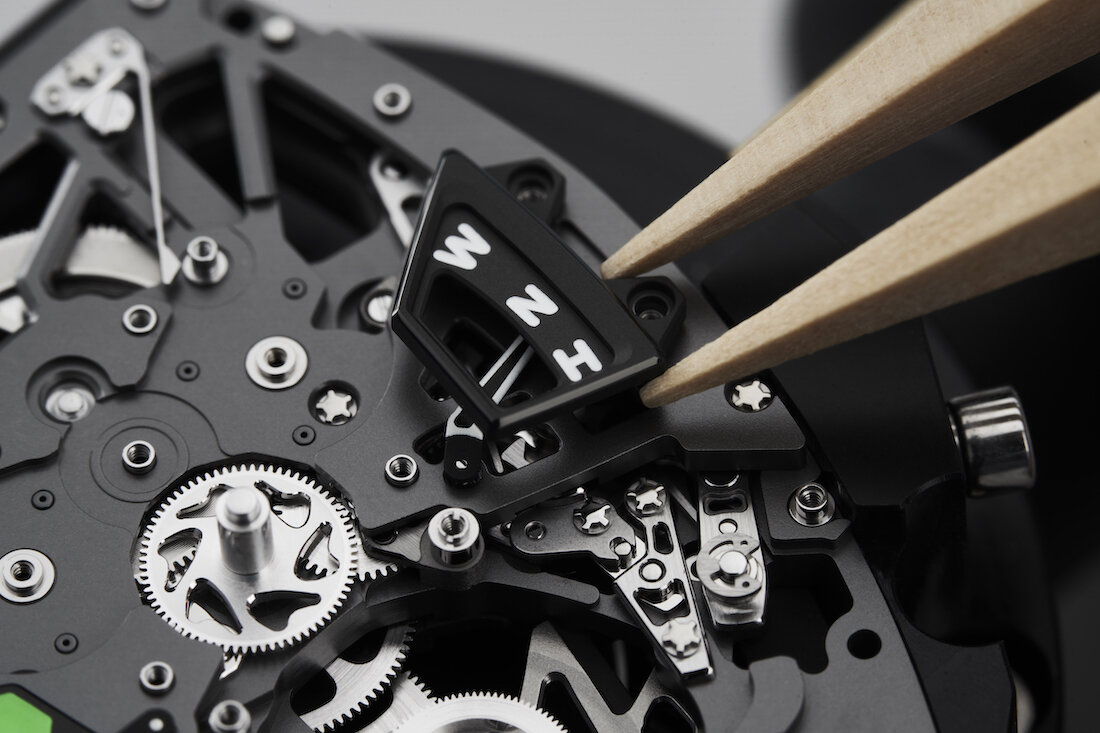

The new Richard Mille RM 40-01 Automatic Tourbillon McLaren Speedtail was released yesterday and here’s the assembly process of its impressive calibre CRMT4. This movement is an automatic winding tourbillon movement with hours, minutes, variable-geometry rotor, oversize date, power reserve indicator, and function selector. The entirely new automatic movement architecture demanded a remarkable 8,600 hours of development, much of which went into finalizing the extreme level of detail. Grade 5 titanium has been used for key components such as the bridges, the bridge screws, the baseplate, and the rotor core.

The CRMT4 movement introduces a power reserve display as well as the oversized date and function selector complications, all of which are firsts at Richard Mille for an in-house tourbillon. The wheels are machined with McLaren logo that adorns the bonnet of the Speedtail, while the domed parts usher in new surface profiles that were required to translate the car’s curves. The movement measures 30.48 mm x 35.35 mm x 6.81 mm, includes 37 jewels, and is equipped with a free-sprung balance with variable inertia. This type of balance wheel represents the ultimate in innovation. It guarantees greater reliability when subjected to shocks and during movement assembly or disassembly, hence better chronometric results over time. The regulator index is eliminated, and more accurate and repeatable calibration is possible thanks to four small, adjustable weights located directly on the balance.

A casing ring is no longer used, and the movement is mounted on chassis mounting rubbers —ISO SW— fixed by titanium screws. The variable-geometry rotor —a signature of Richard Mille automatic timepieces— features an oscillating mass in platinum with a core made of grade 5 titanium and a weight segment in red gold. The platinum and red gold winding rotor is inspired by the McLaren Speedtail’s bonnet and the barrel-setting by its roofline. The guide rail is in black PVD-treated metal with ceramic ball bearings and features a Oneway automatic winding.

This variable-geometry rotor makes it possible to adjust the winding function to the owner’s activity level. Adjusting the weight, which can be slid sideways into the correct position and fixed in place by two spline screws, modifies the setting. The inertia of the movement is optimal when the weight is closer to the external outside edge, and the barrel thus rewinds more quickly. If the weight is positioned at the center of the rotor, inertia is decreased and the barrel winds more slowly.

The Richard Mile RM 40-01 Automatic Tourbillon McLaren Speedtail can be summed in five prototypes that were developed, 8,600 hours of development for the movement construction, 672 components, a 5000 g-shock test, and 18 months of development for the new case shape. Every component on the movement is exquisitely finished including hand-polished anglage, hand-polished stepped bevelling, Microblasted milled section, Microblasted sinks, PVD treatment for the bridges, and electro plasma treatment for the baseplate.

The entire going train of the watch, the primary transmitter of power throughout the movement, utilizes a special profile for the teeth of the wheels, ensuring a 20-degree pressure angle. This system equalizes any discrepancies that might arise between the centres of each wheel, for instance due to thermal changes and normal use, and promotes the smooth transmission of torque to the balance wheel, thus supporting excellent chronometric results. Additionally, the use of spline screws in grade 5 titanium for the bridges and case allows for better control of the torque applied to screws during assembly. These screws are unaffected by physical manipulation during assembly or disassembly and age well.

The new Richard Mille RM 40-01 Automatic Tourbillon McLaren Speedtail is available in a limited edition of 106 pieces.

Sticker Price $1,022,000 USD. For more info on Richard Mille click here.